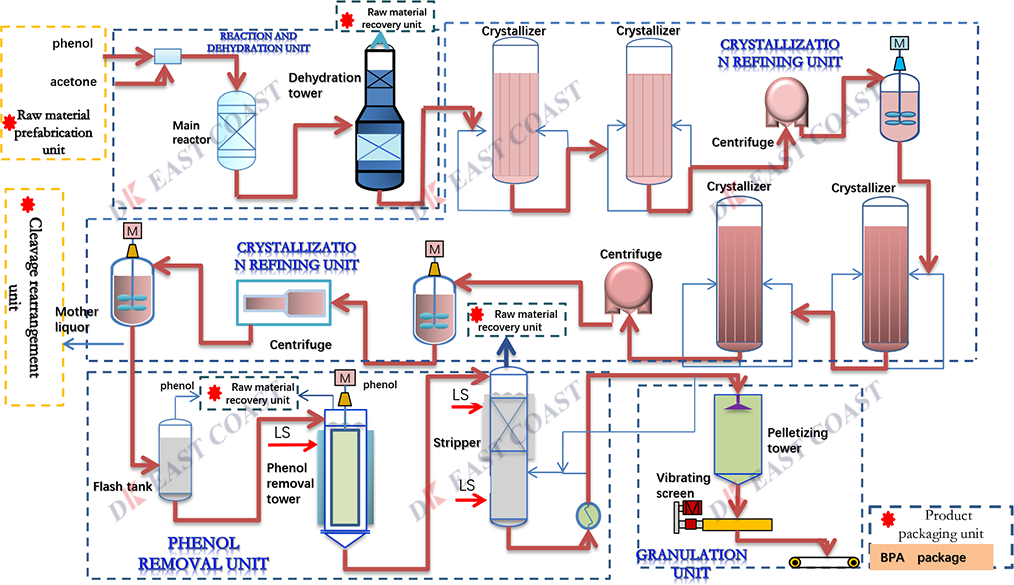

This technology is a continuous process of bisphenol A by ion exchange resin method. It is convenient to start and stop, the product quality is high and stable, and the operation flexibility is large. The same device can produce products of different levels.

The investment cost of this technical project is low. The cation exchange resin is used as the catalyst in the reaction, which is non-corrosive and the catalyst is easy to separate.

This technology has very little pollution, and only contains a small amount of waste water with a very low amount of phenol and acetone; solid waste and waste gas are used as internal fuel in the process, and no additional treatment is required.